Description

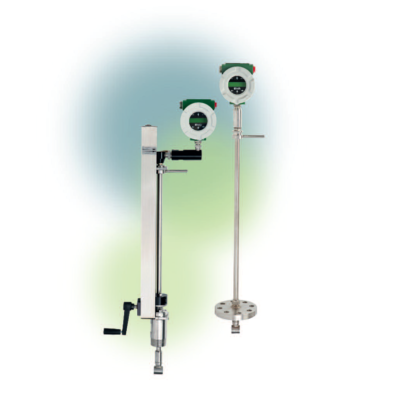

The Model M24 Multivariable Vortex Flowmeter provides volumetric or mass flow monitoring of most liquids, gases, and steam all in one single device. The multivariable design allows for measurements of volumetric flow, mass flow, temperature, pressure, density, and energy (BTU) by utilizing a high-accuracy velocity sensor, a precision platinum RTD temperature sensor, and a solid-state pressure transducer. This allows for reduced complexity, equipment and installation costs when compared to multiple stand-alone instruments when the various process measurements are required.

A reduced bore option is also available (Model M24R) to help match the line size with integrated reducing flanges. This helps to increase the fluid velocity through the meter, which extends the meter’s measuring range to capture lower flow rates that might otherwise be missed in a full line size meter. The reduced bore design eliminates the need for separate pipe reducers and spool pieces, reducing the complexity and costs of the meter installation

Features & Benefits

- High accuracy with rangeability up to 100:1

- Suitable for temperatures up to 400°C (750°F)

- Suitable for pressures up to 1500 psig

- Reliable – no moving parts, no fluid to sensor contact

- Energy Monitoring – ability to compute and output energy use

- Two wire loop powered design saves on energy costs

- HART Protocol communications standard

- Modbus / BACnet communications available