Description

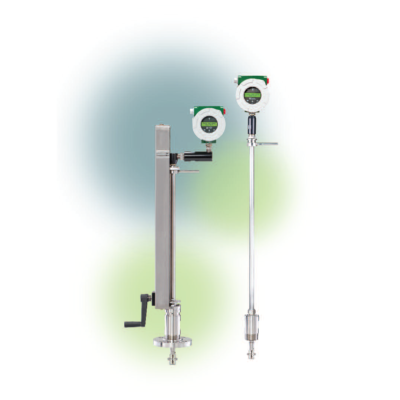

VorTek Instruments’ Pro-V Flowmeters utilize three primary sensing elements – a vortex shedding velocity sensor, an RTD temperature sensor and a solid state pressure transducer to measure the mass flow rate of gases, liquids and steam.

Systems that use external process measurements to calculate mass flow may not provide adequate compensation for the fact that process conditions can change radically between the point of velocity measurement and the point where upstream or downstream pressure and temperature measurements are being made. Due to the fact the Pro-V multi-variable flow meter measures all of these parameters in a single location; it delivers a more accurate process measurement.

Features & Benefits

- Volumetric or mass flow monitoring of most liquids, gases and steam

- Energy Monitoring – ability to compute and output energy use

- Easy to install and commission

- Reliable; no moving parts, no fluid to sensor contact

- High accuracy with rangeability up to 100:1

- Temperature up to 750 degrees F/ 398 degrees C

- Pressure up to 1500 psig

- Field configureable ranges, outputs and displays

- 4-20mA loop-powered Mass Meter design saves on energy costs

- HART protocol communications Standard

- Modbus, BACnet communications available